If you are looking for a low-cost development platform for adding to your low-cost, versatile, credit-card sized, single board computer, the Raspberry Pi or RBPi, a startKIT might be just what you need. With a startKIT attached to your RBPi, you can have real-time Input/Outputs and several communication features including networking and audio, making it an ideal platform for varied applications such as digital audio, networking, motion control and robotics.

This ultra-low-cost development platform for the RBPi is made by XMOS, featuring the configurable multicore micro-controller technology – xCORE. These are an innovative family of devices that you can configure with software for a wide variety of interface and peripheral blocks. Equipped with header connections, startKIT can easily be interfaced to RBPi products. That makes it the ideal real-time IO solution for projects involving the RBPi.

XMOS provides free-to-use design tools along with the startKIT. These xTIMEcomposer design tools offer developers the right interface configurations, allowing them to write application codes quickly, using C/C++, all within a single programming environment. Developers get a full graphical development with the xTIMEcomposer, which includes a compiler, a static time analyzer, a software-based logic analysis tool and a debugger.

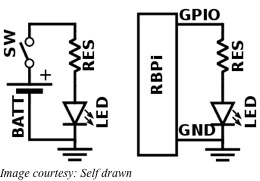

The entire board of the startKIT measures just 94x50mm. The kit is based around the xCORE-Analog multicore micro-controller, the XS1-A8-64-DEV. The xCORE runs at 500MIPS and has eight numbers of 32-bit logical processing cores. Along with the multicore micro-controller, the startKIT comes with an array of LEDs, 2 capacitive sense sliders, a push-button switch and a sliceCARD connector. The sliceCARD connector is compatible with several IO slices that XMOS makes available. You can connect the startKIT board to a breadboard system, as it is equipped with suitable header connectors.

For new users to start with the startKIT, XMOS provides several wide-ranging example codes. These include a web-server application, a software-defined Ethernet interface and the basic driver software necessary for operating the on-board LEDs and the push-button. If you want more, you are free to join the XCORE Exchange, a thriving community of users at xCORE; you will have access to a large variety of xCORE code.

The on-chip debug capabilities of the on-board xCORE multicore micro-controller, XS1-A8-64-DEV, allows the developer an in-circuit analysis of the complete design in comprehensive real-time. That makes it easy to see what is happening in real-time at the device interface and in the code – while the system is running – all without affecting the performance. You can also monitor the analog interfaces alongside the digital signals of the startKIT. For example, you can monitor the signals on the capacitive touch-sensors in real-time.

For those who work with applications such as digital audio, networking, motion control and robotics, the eight 32-bit logical cores of the 500MIPS xCORE multicore micro-controller can perform deterministically. Therefore, you can configure the startKIT to match your exact requirements as the software allows you to configure the interface.

The xCORE-Analog A8-DEV is a two-tile device. While Tile-0 handles the integrated debugger and USB PHY, Tile-1 is dedicated to the user-programmable eight logical cores, with its digital IO available on pins. That allows several types of peripherals to be integrated with the startKIT board.