What Are Gray Market Electronic Components – And Are They Safe To Buy?

Chances are the low-cost rechargeable batteries that you ordered over the net failed after one or two cycles of operation. A closer inspection would have revealed the batteries were already past their shelf life when you received them. Welcome to the world of gray market electronic components, which currently forms about 6 to 8% of the total electronic components market, and makes up as much as $60 billion dollars’ worth.

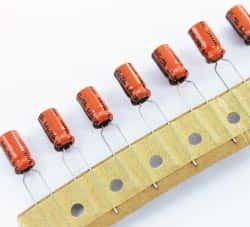

Not only outdated components, even parts rejected (and preferably destroyed) by manufacturers, find their way in the supply chain. It is only after soldering the components and sending them for testing does the realization sinks in that they are not genuine. In the $300 billion semiconductor industry, such bogus components have an annual impact of up to $20 billion.

Apart from this, the gray market is also a known issue for unauthorized sale of new and branded products diverted from the authorized channels of distribution. The gray market not only makes the high-tech companies suffer, it also affects negatively consumers and other end-users of technology, such as the military and the defense. Products advertised as new and authentic could in reality be refurbished after use. They could even be counterfeit. Using counterfeit or non-conforming parts could have significant effects on the performance of the product. In the case of defense and military, these effects could also be catastrophic.

Components Direct recently conducted a study for a leading semiconductor supplier. They found over 90 million units of the products, both analog and digital devices, with over 7,000+ part numbers, were floating in the gray market. Over 80% of the products were in the Asian gray market, and 8% appeared in the EMEA (Europe, the Middle East and Africa) and North America. More than 29% of their gray market product had date codes of less than one year, although the product age spanned several years. Nearly 15% of these products had date codes more than 11 years old.

This demonstrates that no end consumer is immune to unauthorized products, irrespective of whether you are a military sub-contractor searching for obsolete components, or an OEM (Original Equipment Manufacturer) looking for new products.

As the chain of supply has numerous potential points of entry, and the ability to trace the path of the product flow remains limited. This makes the gray market problem a prevalent one in most product categories. The multiple points of entry provide unlimited opportunities for unscrupulous individuals, partners or counterfeiters.

The impact of the gray market is significant and long-term. This affects the revenue, cost, brand reputation, liability and risk of the entire chain of supplies. After sales support for the product may be non-existent or it may affect the company’s profitability to maintain support since no one has paid the applicable support. This also affects the end-user operationally and financially, and it may tarnish the manufacturer’s reputation because of the lowered satisfaction of the end-user with the brand

So how do you protect yourself? Look for component suppliers that are stocking distributors. Take to the search engines to see if there are reports of the supplier having supplied bad or counterfeit parts in the past. If you are unsure, buy a sample and have it tested. While there are some scammers out there, there are also many honest and hard-working small businesses that deserve your business.